IR lens design

Our company’s R&D team has more than 20 peoples with excellent ability for optical design, structure design and various technology analysis. We can quickly provide the best solution and customization service for our customer. If you have design requirements please send us parameter or describe the desired effect.

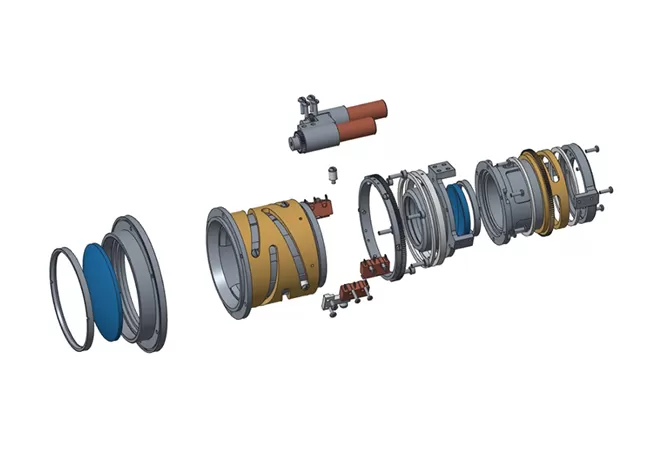

Mechanical Parts and Optical Component Processing

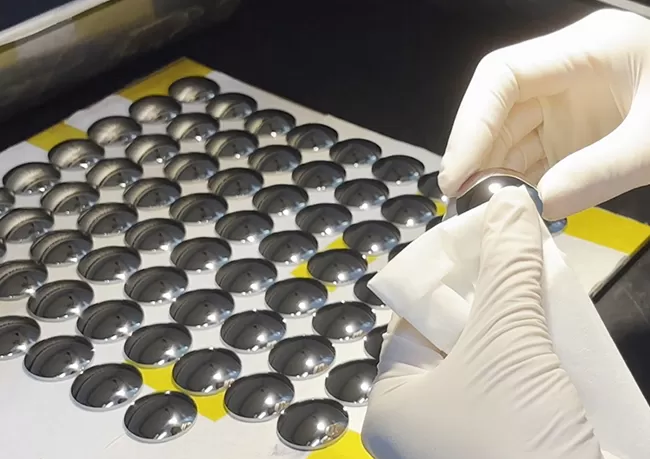

Optics is a core technology for IR Lens, and the lenses that comprise optical systems are important parts that determine a product's performance. Our company has ultra-precision single-point diamond lathe, polishing machine, and other equipments, which can process various optical components such as spherical, non spherical, diffractive, off-axis non spherical, etc. Also has a high level of coating technology for AR, DLC, HD, reflective and filter films.

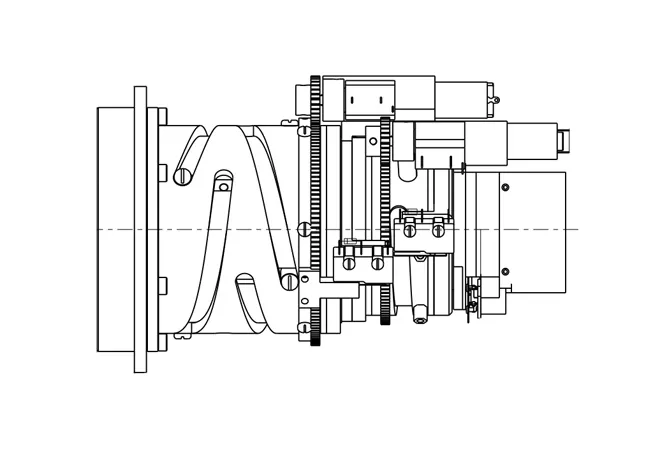

High precision processing equipment can ensure that the mechanical parts meet the design requirement. Including ultra-precision CNC lathes, five-axis machining centres, high-precision wire cutting, and is capable of processing shaped optical parts and a variety of high-precision mechanical parts.

We can not only provide customers with professional parts design and processing guidance, but also provide customers with quality processing services.

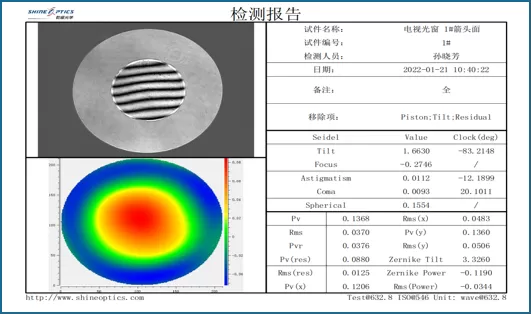

Inspection

Our company has a perfect inspection team to inspect the optical components and mechanical structure parts very strictly, to ensure that the geometric dimensions, such as diameter, thickness tolerance and so on to maintain consistency with the design parameters. And make full use of advanced measuring equipment, such as Zeiss coordinates, double optical path centre bias, laser profilometer and so on. We can control the quality from the source.

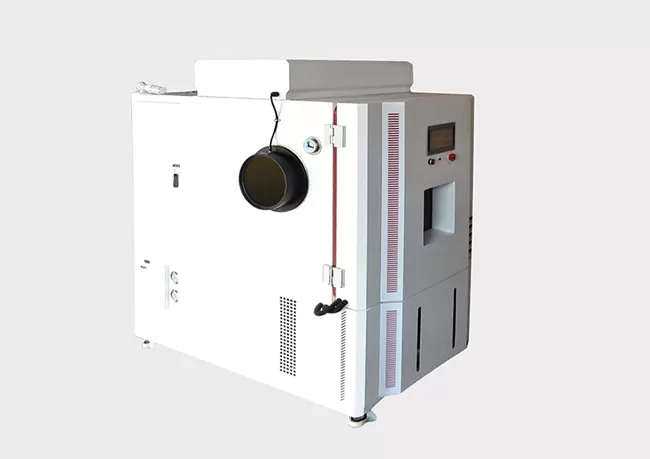

Assembly and Testing

The precision optics assembly and adjustment process is the last key process in the manufacturing of precision optical lenses. It involves the mechanical assembly and adjustment of optical components to ensure that the performance of the entire optical system meets the design requirements. Through the precision optical machine mounting and adjustment process, the errors generated during the manufacturing and assembly process can be eliminated, and the image quality and performance of the optical system can be optimised, so that the lens can give the best results in practical applications. A variety of testing equipment, such as altimeter, centrifuge, thickness gauge, etc., are complete to ensure the quality requirements of the products from the factory.

After-sales Service

We have a professional after-sales team, always focuses on customer needs, and provides a full range of efficient services. It is easy to solve the problem for manufacturing company.

Customization Process

01

Requirement Analysis

Initially, please let us know your requirements, a preliminary concept or paramater list.

02

Material Selection

Like germanium and zinc selenide are often used due to their excellent infrared transmission.

03

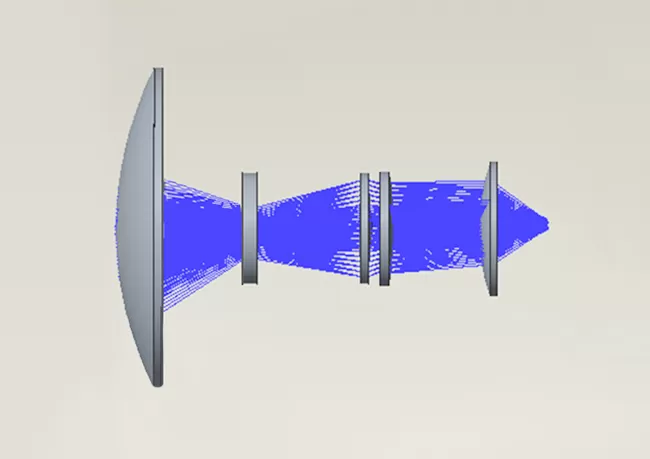

Optical Design

We use advanced software to optimize parameters such as lens curvature, thickness and so on.

04

Manufacturing

Skilled technicians manufacture the lens and structure according to the design.

05

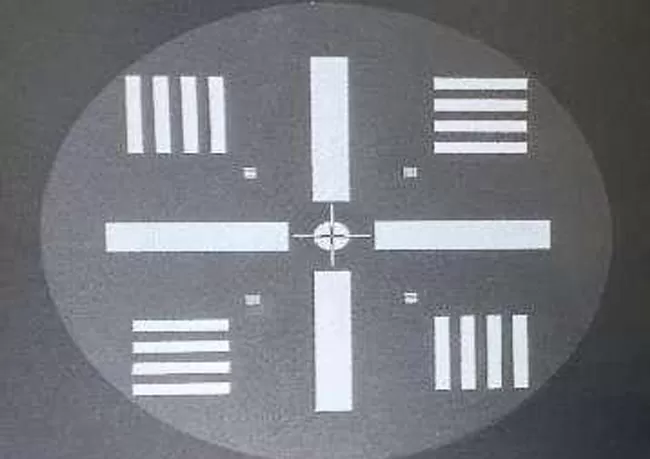

Testing and Calibration

A series of strict tests include testing for imaging quality, focus accuracy and so on.

06

Delivery

Once the lens passes all tests, it is packaged and delivered to the customer.

After-Sales Service

We have a professional after-sales team, always focuses on customer needs, and provides a full range of efficient services. It is easy to solve the problem for manufacturing company.